1 / 4

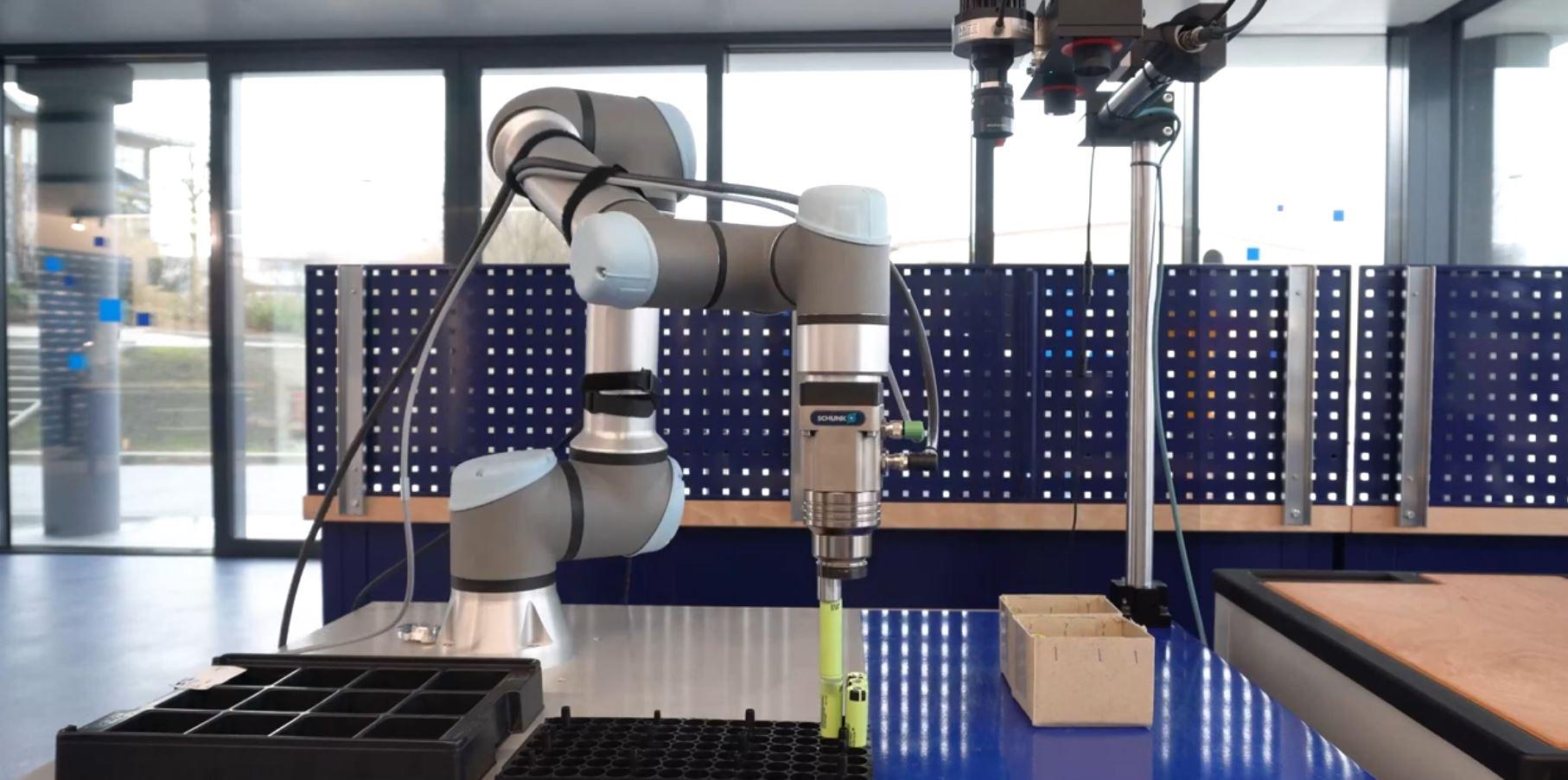

1 / 4Robot Cell - Bin Picking

Hardware Price:

DOF

5

Repeatability

1

mm

Max. velocity

0.2

meters per second

Intuitive Pick-and-Place Automation: Productivity Without IT Expertise

Industrial companies, especially SMEs, often face challenges in adopting Industry 4.0 due to a shortage of IT specialists. To address this, Commonplace Robotics and igus have developed an easy-to-operate robot cell. Featuring the robolink robot arm, this solution handles tasks such as feeding components into CNC milling and injection molding machines. With Windows-based CPRog software, employees with no IT experience can set robot movements through a simple digital twin interface, making automation accessible for all.

What is the Application?

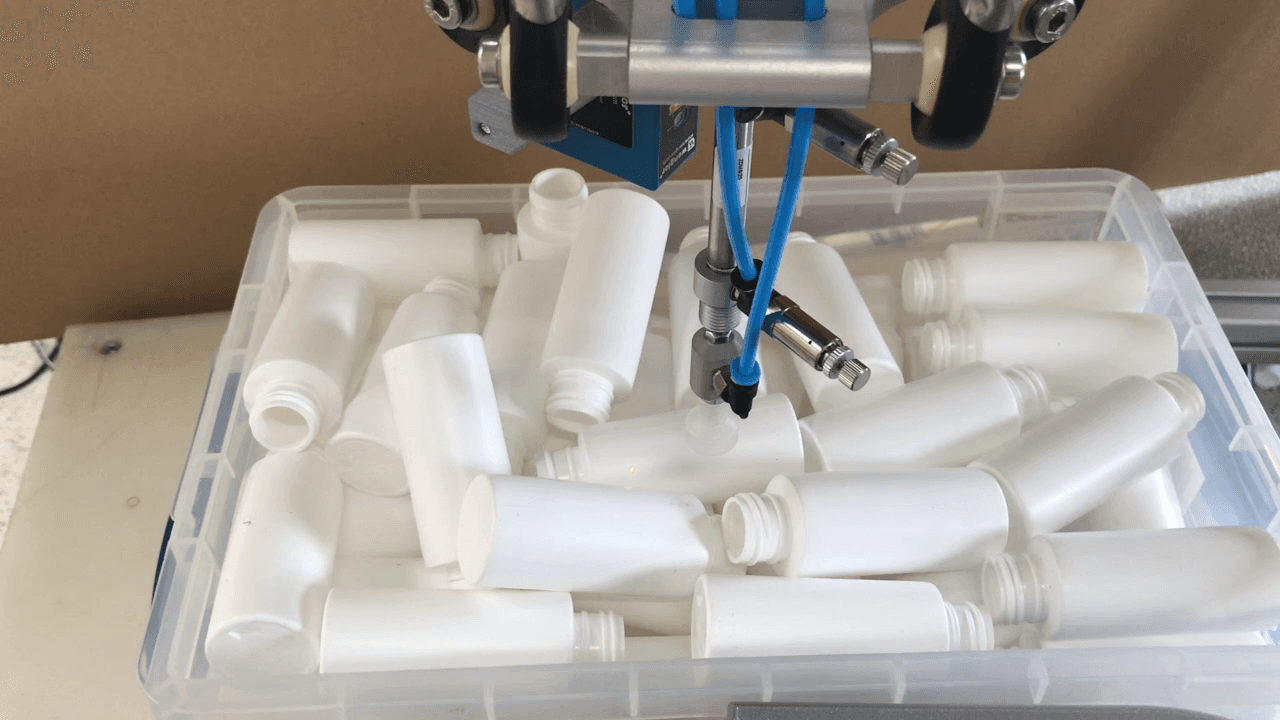

The robotic system automates pick-and-place operations, such as transferring components from crates into industrial machinery. A 3D camera identifies unsorted parts, enabling precise handling.

What are the Advantages of the Solution?

Ease of Use: Intuitive software eliminates the need for IT expertise.

Increased Productivity: Reduces worker burden, enabling focus on higher-value tasks.

Cost Efficiency: Affordable components ensure a rapid ROI within 5 months.

What are the Advantages of the Robot?

The robolink arm offers reliable automation for demanding tasks:

Precision: Achieves repeat accuracy of 0.8 mm at seven picks per minute.

Durability: High-performance plastic joints enable maintenance-free operation.

Affordability: Components are cost-effective yet highly functional.

Affordable Automation for Industry 4.0 Transformation

This robotic solution bridges the gap for SMEs hesitant about automation. With its intuitive interface, accessible pricing, and reliable performance, it provides a low-risk entry into Industry 4.0. Companies can increase productivity, improve efficiency, and reduce costs, making automation a sustainable and scalable addition to their operations.

3 Components