1 / 3

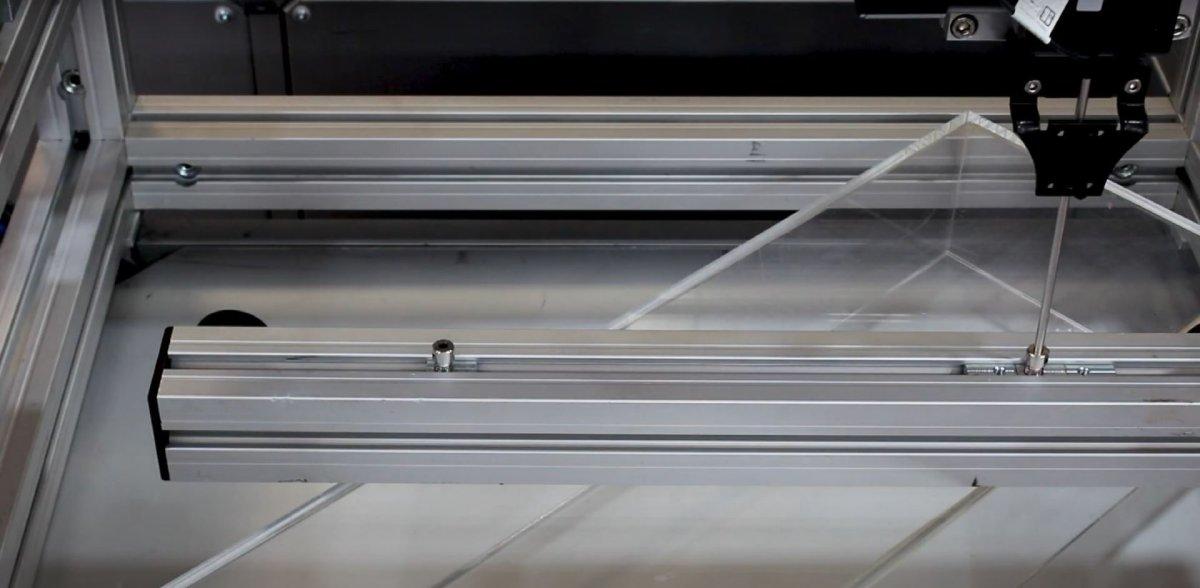

1 / 3Precise pick & place application

Hardware Price:

DOF

3

Working space

500x500x100

mm

Repeatability

0.8

mm

igus XYZ Gantry Systems: Precision and Versatility in Automation

XYZ gantry systems provide a powerful combination of high speed and precision, making them essential for handling demanding and customized automation tasks. In this example, an igus room linear robot demonstrates its precision capabilities. Built for lubricant-free gliding, the gantry system ensures low-maintenance operations, keeping costs minimal while delivering consistent performance. Its modular design allows the working spaces to be tailored to individual project requirements, making it ideal for a wide range of applications.

What is the Application?

XYZ gantry systems automate precise material handling, sorting, or assembly tasks, offering scalable solutions for industries like manufacturing, logistics, and prototyping.

What are the Advantages of the Solution?

Customizable Workspace: Easily adapts to unique project requirements.

Low Maintenance Costs: Lubricant-free design minimizes service needs.

High Precision: Consistently accurate movements enhance performance.

What are the Advantages of the Robot?

igus XYZ gantries excel in precision-driven workflows through:

Modular Flexibility: Custom working spaces for diverse applications.

Cost-Effectiveness: Economical solution for advanced automation.

Robust Durability: Runs smoothly and reliably without frequent maintenance.

Maximizing Automation Efficiency with igus XYZ Gantries

igus XYZ gantry systems are adaptable, precise, and cost-efficient solutions for modern automation requirements. By combining modular customization, low maintenance needs, and reliable precision, they offer industries a scalable and effective way to tackle demanding workflows and improve productivity.

1 Component